New breakthrough in rare earth permanent magnets, Ningbo Magnetics visits new equipment

time2024/10/26

- Recently, the research and development team of a magnetic company in Ningbo made a special trip to Zhejiang Institute of Magnetic Materials for an in-depth technical exchange and field investigation.

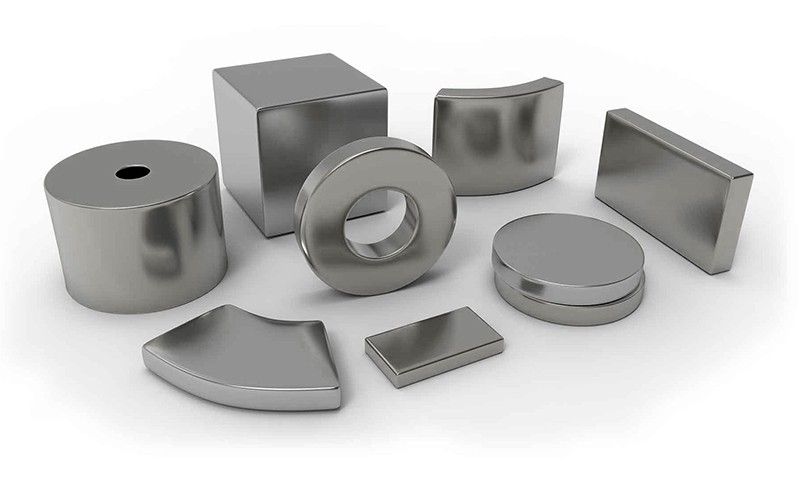

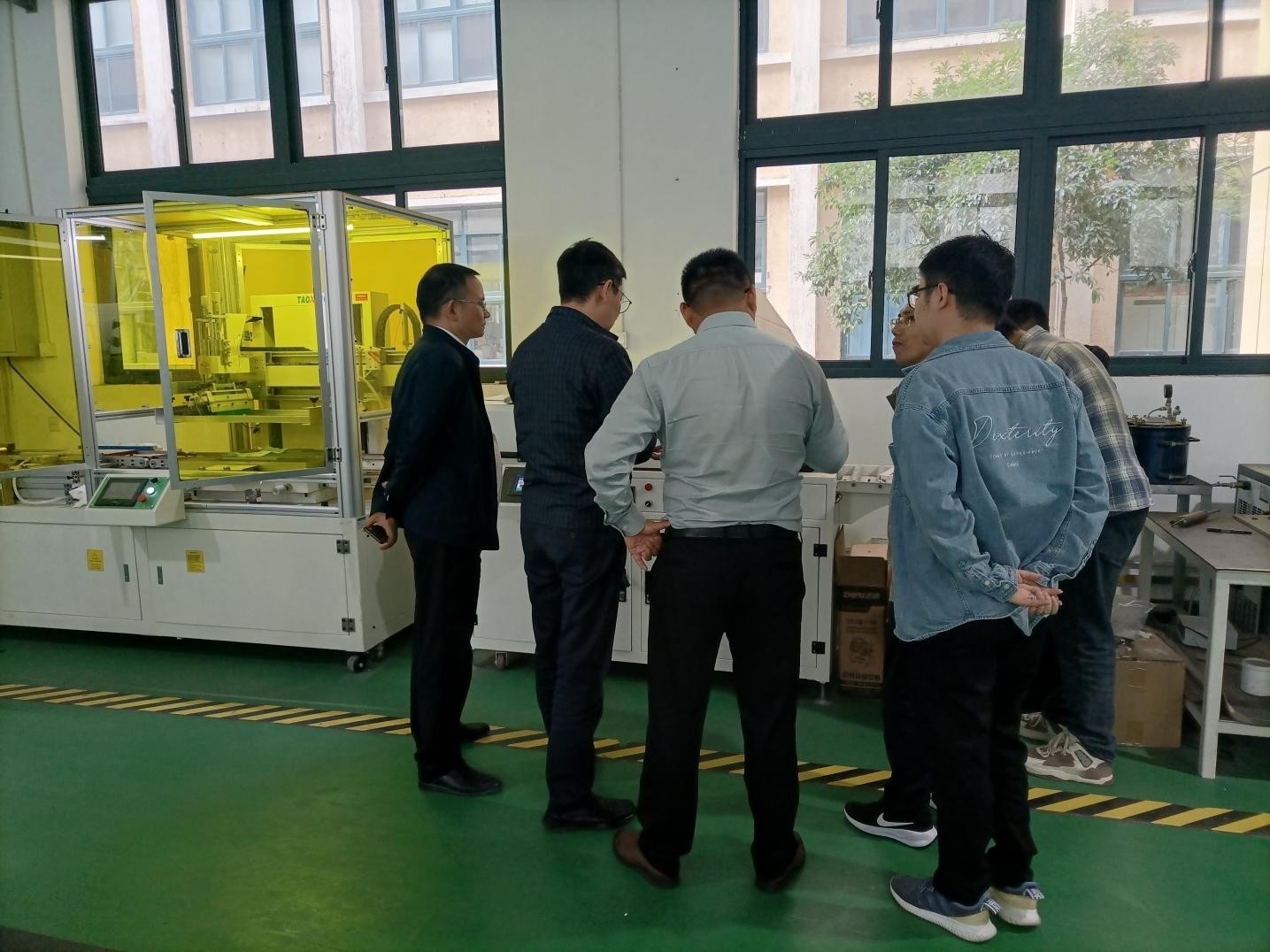

Recently, the research and development team of a magnetic company in Ningbo made a special trip to Zhejiang Institute of Magnetic Materials for an in-depth technical exchange and field investigation. The focus of this visit was on the new laser curing screen printing equipment jointly developed by Hangzhou Dianzi University and Hangzhou Taoxing Printing Equipment Co., Ltd. The application potential of this cutting-edge technology equipment in the field of rare earth permanent magnet materials has aroused great interest among team members.

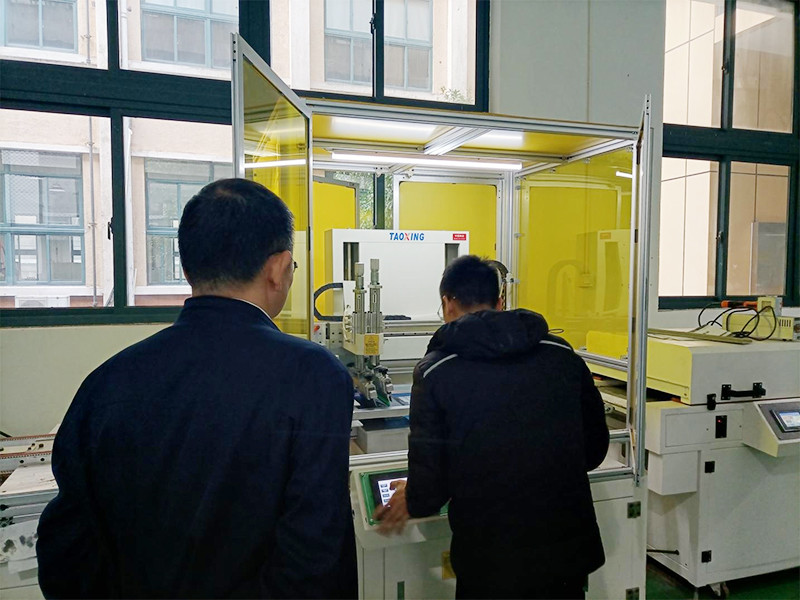

Accompanied by experts from the Institute, the technical team of the Magnetics Company first watched the on-site demonstration of the new laser curing screen printing equipment. The equipment combines high-precision laser beams with rare earth permanent magnet materials to achieve rapid and accurate printing and curing of grain boundary diffusion products on the surface of permanent magnets , greatly improving production efficiency and product quality. During the demonstration, the high efficiency, low energy consumption and excellent printing accuracy of the equipment amazed every technician present.

Afterwards, the two sides held an in-depth discussion. Researchers from the Magnetic Materials Research Institute of Hangzhou Dianzi University introduced in detail the R&D background, technical principles, performance indicators and application cases of the equipment in the preparation of rare earth permanent magnet materials. The technical team of the magnetic industry company that came to inspect the equipment raised many questions about the applicability, ease of operation and maintenance cost of the equipment in actual production based on their own needs, and received detailed and professional answers from experts from the institute.

Through this visit and exchange, the technical team of the magnetic industry company not only gained an in-depth understanding of the latest technical developments of the new laser curing screen printing equipment, but also conducted preliminary discussions on the possibility of future cooperation in the research and development and production of magnetic materials. Both parties expressed that they will further strengthen communication and exchanges to jointly promote technological innovation and industrial upgrading in the field of magnetic materials.