Powder Coating Machine Hot Melt Powder Glitter Powder EVA Foam Sheets Coating System

- group name

- Glitter Powder Sprinkler

- Min Order

- 1 set

- brand name

- TAOXING Screen Printing Machines Manufacturer

- model

- TX- SF100D

- Nearest port for product export

- Shanghai, Ningbo, Shenzhen, Yiwu

- Delivery clauses under the trade mode

- FOB, CFR, EXW

- Acceptable payment methods

- T/T, D/P D/A, Credit Card, PayPal, Westem Union

- update time

- Sun, 01 Mar 2026 15:34:30 GMT

Paramtents

Model TX- SF100D

Suction type Single suction

Max.dusting width 1000mm

Max. thickness 5mm

Power 2.0KW 220V 50Hz

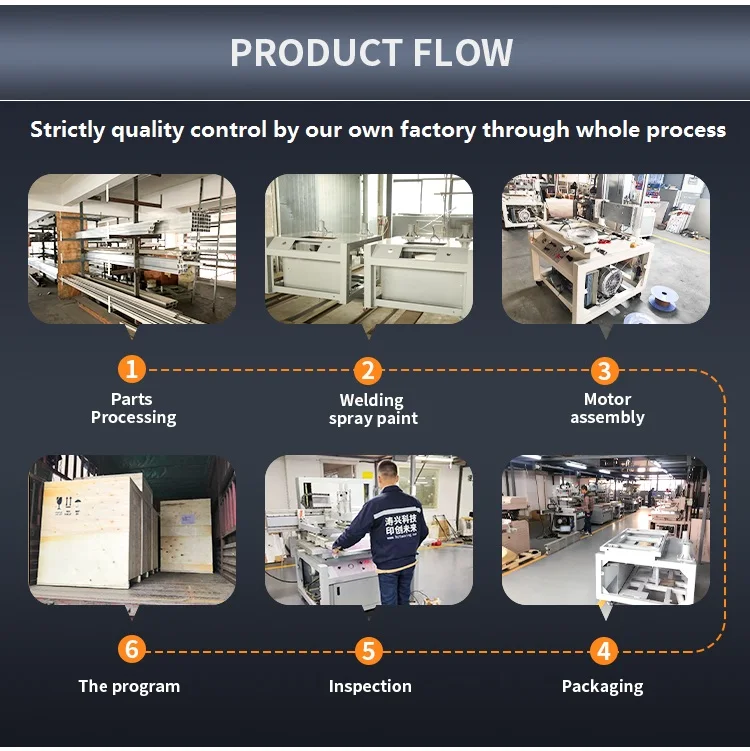

Packging & Delivery

-

Min Order1 set

Briefing

Detailed

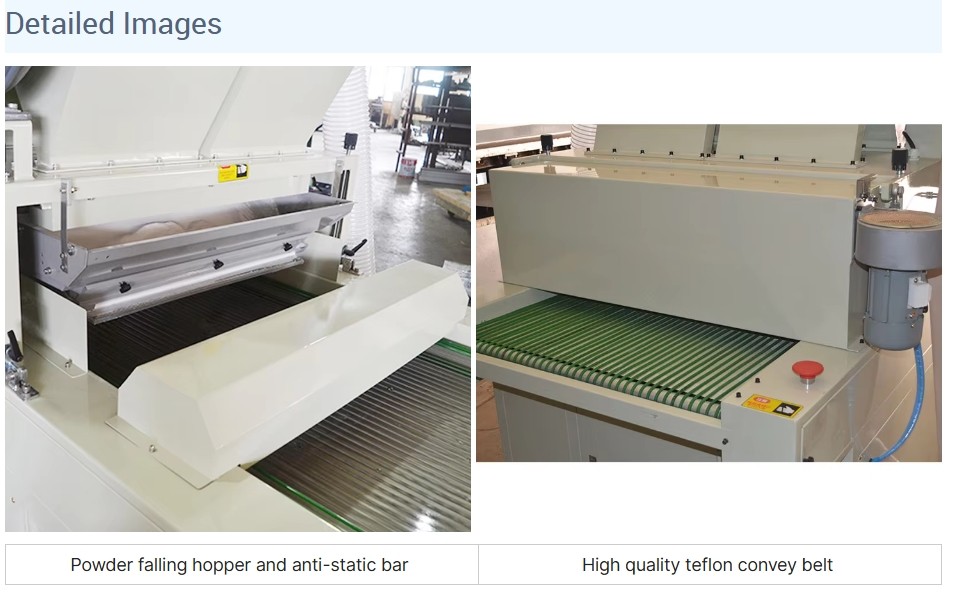

Glitter powder spraying machine is a post-printing equipment that replaces the traditional manual glitter powder sprinkler. It is suitable for the powder sprinkler process on couplets, blessing characters, greeting cards, Christmas pictures, handbags, and EVA toys. It has the function of powder sprinkler and residual powder recovery in one go. It is easy to use, flexible to adjust, high in work efficiency, and free of dust pollution. All transmission parts of the machine are frequency-controlled and can be directly connected with a fully automatic screen printer or gluing machine. It can achieve perfect results for the glitter powder sprinkler process of paper and EVA with high surface requirements. If the process requires, it can be directly connected to a drying device or UV light curing device after the machine.

Application

Product Parameter

We sell printing machines to customers all around the world helping printers produce high quality work with speed, efficiency and reliability in over 70 countries. And developed more than ten distributors covering of big Continents.

Why Choose Us