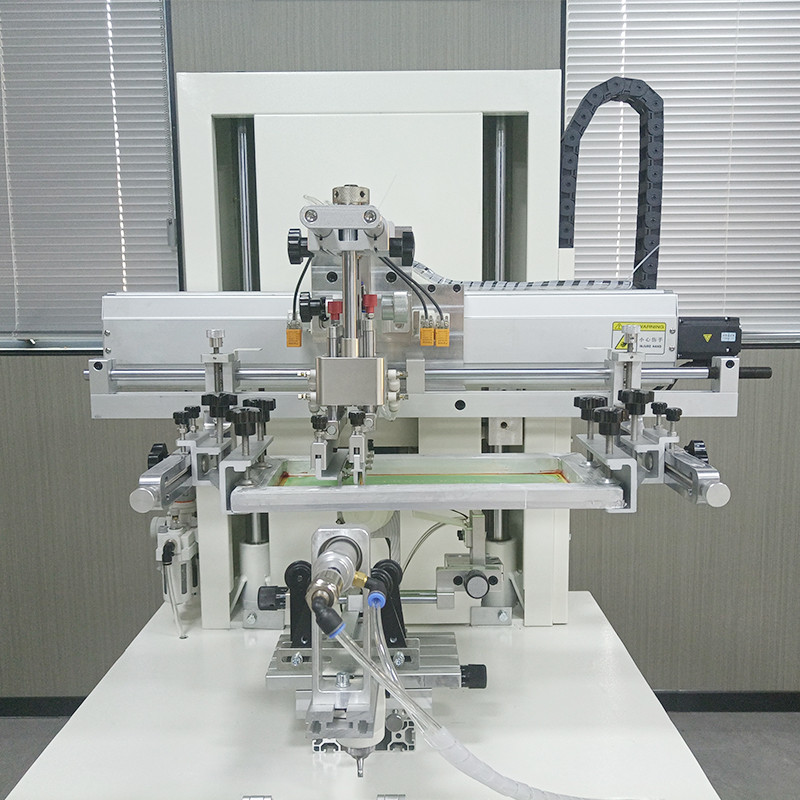

TAOXING Servo Curved Screen Printing Machine TX-500SF For Round Products

- group name

- Curved Screen Printing Machine

- Min Order

- 1 set

- brand name

- TAOXING Screen Printing Machines Manufacturer

- model

- TX-500SF

- Nearest port for product export

- Shanghai, Ningbo, Shenzhen, Yiwu

- Delivery clauses under the trade mode

- FOB, CFR, EXW

- Acceptable payment methods

- T/T, D/P D/A, Credit Card, PayPal, Westem Union

- update time

- Thu, 18 Sep 2025 18:59:20 GMT

Paramtents

Max printing area 500*200mm

Substrate Diameter ≤160mm

Printing Speed 800pcs/hour

Max screen frame 700*350mm

Max Printing length 300mm

Machine Weight 272kg

Power Supply 220V,50/60/Hz/100W

Machine Dimension L1040*W990*H1700mm

Air pressure 4-6kgf/cm2

Application Areas Cups, bottles, cans, metal pipes,

Packging & Delivery

- 120cm x100cm x170cm

-

Min Order1 set

Briefing

This servo curved screen printing machine is suitable for surface pattern printing of various round products.

Detailed

Introduction TX-500SF Servo curved screen printing machine

This servo curved screen printing machine is suitable for high-precision printing of various cosmetic eyebrow pencils, containers, pharmaceutical containers, food containers, electronic devices, toys, cabinets and other surface patterns and text.

Main parameters

Model : TX-500SF

Max Printing area: 200*500mm

Air pressure: 5 bar

Rated voltage/Power: 220V/50HZ/1000W

Max printing speed: 800-1000(PCS/H)

Max screen frame: 300*600mm

printing size: Φ150*200mm

Printing length: ≤250mm

Dimension Size : 1150*950*1600mm

Gross weight : 272(KG)

Features:

Compared with ordinary curved surface color registration, it is more convenient that it does not require positioning points, and the infrared light eye has higher positioning and color registration accuracy, which is suitable for enterprise product development and small batch printing.

This screen printing machine is available to print on plastic, glass and metal goods, like cups, plastic bottles, glass bottles, pistons, bottle ROPP caps, jars, plastic flexible cosmetic soft tubes and so on. Widely used for industries of daily chemical, food,beverage, pharmaceutical, chemical, personalized water bottle business, cosmetic bottle manufacture, etc.

Main performance

1. PLC programming, touching screen, simple to operate, easy to use

2. Built in digitalcounts for production output

3. Facilitate to placement of the productbenefit from special design famous air cylinders

4. Servo motor drive rotating and printing head ensure high precision

5. Self-balance scraper technology and ink cover blade

6. Printing Strokeand rotation by digital adjustments, printing speed controllable.

7. Convenient operating the height of the printing beam by hand wheel.

8. Easy to disassemble and cleaning the screen plate due to the independent design of lifting printing head including scraper

and squeegee;

9. Quality photoelectricity sensor and perfect fault self-detect

10. Metal structure,running steady, foot switch for starter.

Details pictutre

Printing samples