Customized IR Hot Air Drying Tunnel for Screen Printing Line TX-IR600

- group name

- IR Drying Machine

- Min Order

- 1 set

- brand name

- TAOXING Screen Printing Machines Manufacturer

- model

- TX-IR600

- Nearest port for product export

- Shanghai, Ningbo, Shenzhen, Yiwu

- Delivery clauses under the trade mode

- FOB, CFR, EXW

- Acceptable payment methods

- T/T, D/P D/A, Credit Card, PayPal, Westem Union

- update time

- Sat, 28 Feb 2026 03:27:24 GMT

Paramtents

Type Drying Oven

Voltage AC 380V/ 50HZ 3-Phase

Belt width 400mm

Input area 500mm

Heating area 2m each section, customized

Cooling area 1 m or customized

Output Zone 0.5m or customized

Speed 1-10m/min

Max temperature 250 ℃

Max belt Speed 10 Mtr/ Min

Weight 260 KG

Heating Method Electric Heating

Material SUS316, SUS316L, Ti, Other

Dryig process Continuous Automatic Drying

Advantage Low Consumption High Efficiency

Packging & Delivery

-

Min Order1 set

Briefing

IR drying tunnel machine widely apply for screen printing. electronic products, plastic tube, gloss bottle.

Detailed

Introduction IR Drying Tunnel Machine

IR Conveyor Belt Drying Tunnel Machine offered find application in the field of screen printing and are extensively used for

table prints. Being precision engineered, these are based on advanced process technology so as to deliver long working life. Here,the provision of digital display with digital keypad is also provided with reduced energy costs through use of high volume circulation blower.

The general features comprise air handling, use of forced airflow accelerating drying/curing processes, use of high-volume circulation blower that reduces energy costs, separate dedicated blowers for achieving circulation & exhaust control center.

Further, the system also comes with digital keypad with digital display, air-cooled electrical control cabinet for ensuring long life of electrical components as well as conveyor belt made of imported anti static heat-resistant, coated fiberglass coating so as to provide maximum process efficiency standards.

Specification

Application: IR drying tunnel machine widely apply for screen printing, electronic products, plastic tube, gloss bottle.

Model :TX-IR600

Width of belt: 400mm

Power/set:3KW/set

Outside size: according to the demand for custom

Working Power:AC 380V 50HZ

Gross weight: 300kg

Features and Performance

1. Intelligent temperature control system,easy operation

2. adopt hot circulating system to save energy

3. Adjustable belt speed and tunnel temperature controls.

4.customized size

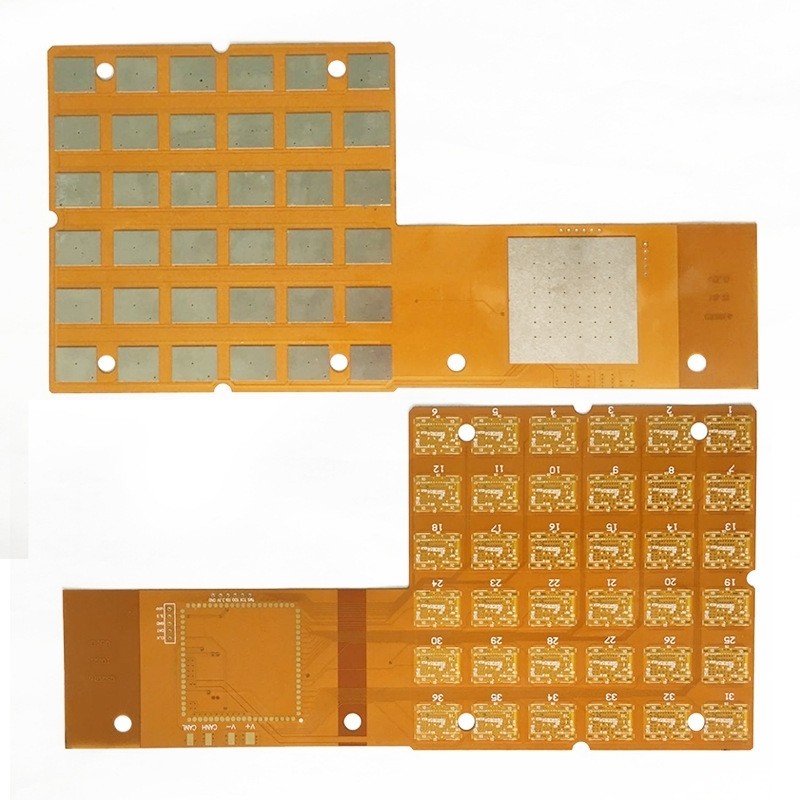

Appearance pictures

Application

Glass Panel

Flexible circuit board

Membrane Switch