Automatic Emulsion Coating machine Screen coater For Screen Printing

- group name

- Screen Coating Machine

- Min Order

- 1 set

- brand name

- TAOXING Screen Printing Machines Manufacturer

- model

- TX-CT3350

- Nearest port for product export

- Shanghai, Ningbo, Shenzhen, Yiwu

- Delivery clauses under the trade mode

- FOB, CFR, EXW

- Acceptable payment methods

- T/T, D/P D/A, Credit Card, PayPal, Westem Union

- update time

- Fri, 27 Feb 2026 16:03:11 GMT

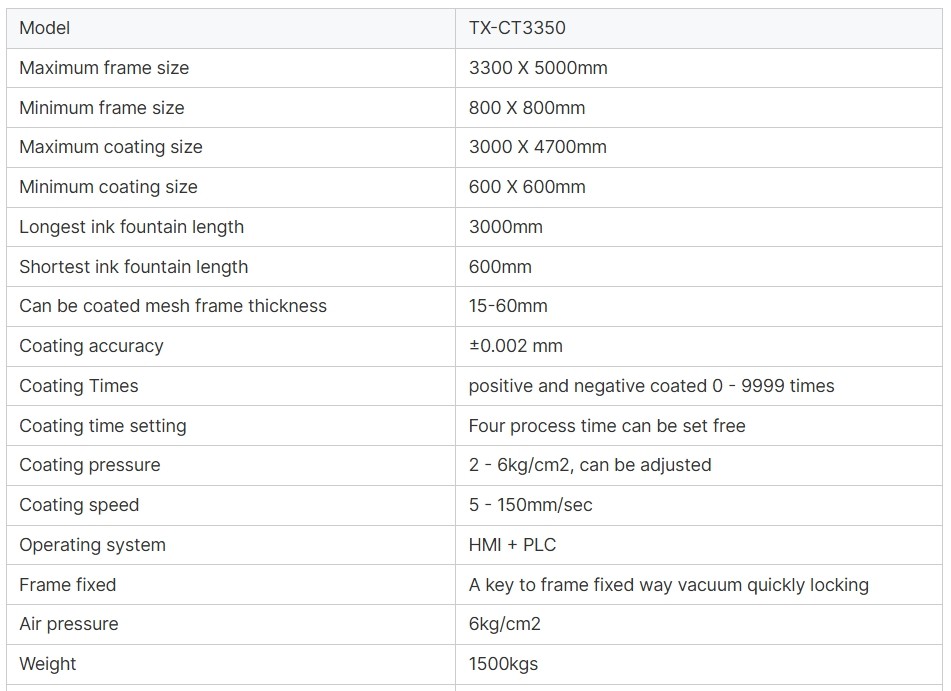

Paramtents

Power Voltage 220V / 50HZ / 2.2KW

Weight 1500 KG

Dimension 4323 x 1225 x 5962 mm

Max frame size 3300 X 5000mm

Machine specifications W4323 x D1225x H5962 mm

Minimum frame size 800 X 800mm

Maximum coating size 3000 X 4700mm

Longest ink fountain length 3000mm

Shortest ink fountain length 600mm

Can be coated mesh frame thickness 15-60mm

Coating accuracy ±0.002 mm

Coating pressure 2 - 6kg/cm2, can be adjusted

Coating speed 5 - 150mm/sec

Operating system HMI + PLC

Air pressure 6kg/㎝²

Packging & Delivery

- 432cm x122cm x500cm

-

Min Order1 set

Briefing

Automatic Emulsion Coating machine is suitable for large-format glass , advertising and other screen printing screen of high-precision coating photographic emulsions.

Detailed

Introduction of Automatic Emulsion Coating machine

Application:

The Automatic Emulsion Coating Machine is primarily used in the screen printing industry to apply a uniform layer of emulsion onto screens. This machine ensures consistent, high-quality coatings that are crucial for producing detailed and accurate prints. Key applications include:

1. Textile Printing: Coating screens for printing designs on fabrics.

2. Graphic Printing: Preparing screens for posters, signage, and other graphic materials.

3. Electronics: Creating precise patterns on screens for printing circuit boards.

4. Industrial Applications: Coating screens used in printing labels, decals, and other industrial components.

Its automation enhances productivity, reduces labor costs, and improves coating precision compared to manual methods.

Features and Performance

(1) using imported motor (SANYUANG) can maintain a low vibration and average.

(2) the speed of coating, coating time can be set freely.

(3) according to the special pressure control device can adjust precision coating.

(4) single coated and double coating can be set freely.

(5) using the touch screen set coating number and speed.

(6) large-format high-precision coating effect can be achieved by ± 0.002 mm.

(7) walking guide with special steel materials to implement low vibration.

(8) choose PLC programmable controller and HMI human-machine interface as an operating control system.

(9) a variety of operating system default language, a variety of coating model, as well as detailed parameter Settings.

(10) key parts using imported brand.

(11) treatment for corrosion resistance of high precision aluminum photosensitive adhesive ink fountain.

(12) overall removable type design, convenient installation.

(13) the machine back against the wall mounting, effectively ensure the safe operation of the equipment.

Specification of Automatic Emulsion Coating machine

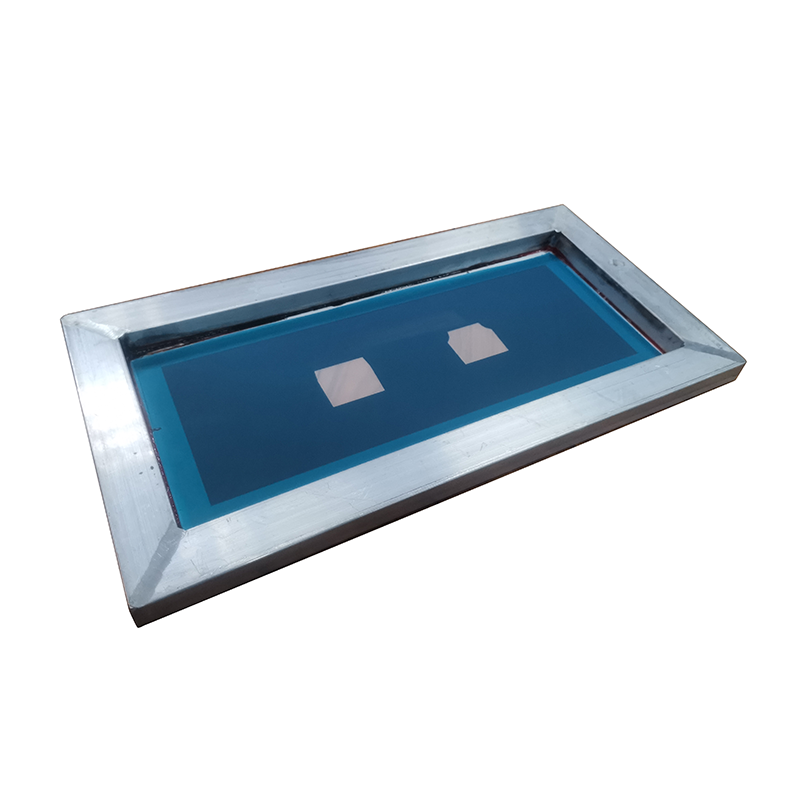

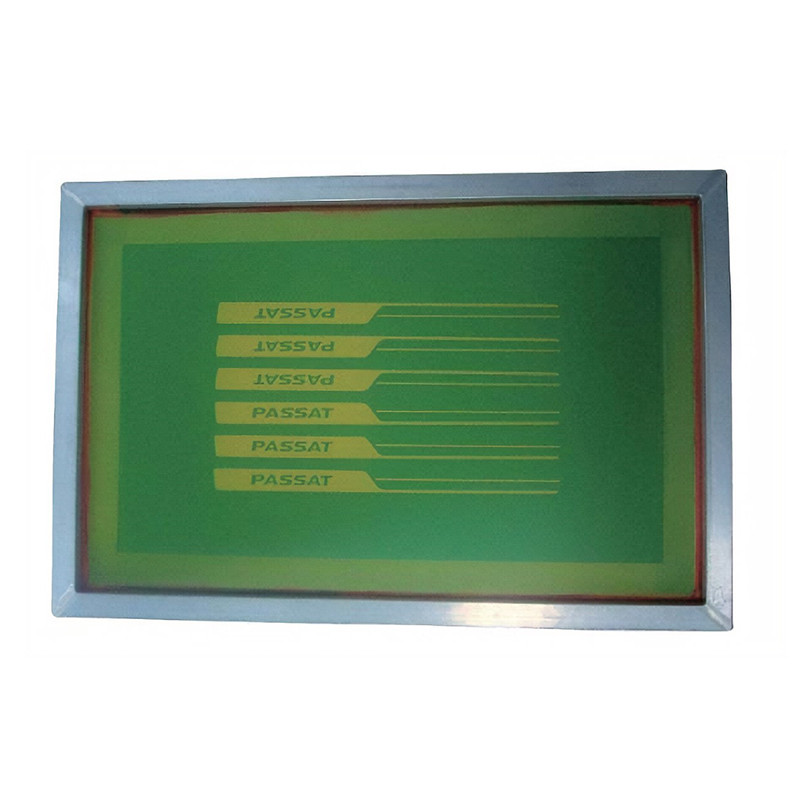

Machine image

Application of Automatic Emulsion Coating machine