Taoxing CCD Registratering Semi-Auto Thick Film Circuit Screen Printing Machine

- group name

- Semi-Automatic Flat Screen Printing Machine

- Min Order

- 1 set

- brand name

- TAOXING Screen Printing Machines Manufacturer

- model

- TX-CCD200A

- Nearest port for product export

- Shanghai, Ningbo, Shenzhen, Yiwu

- Delivery clauses under the trade mode

- FOB, CFR, EXW

- Acceptable payment methods

- T/T, D/P D/A, Credit Card, PayPal, Westem Union

- update time

- Sat, 28 Feb 2026 11:17:07 GMT

Paramtents

Printing size 150mm*150mm

Packging & Delivery

-

Min Order1 set

Briefing

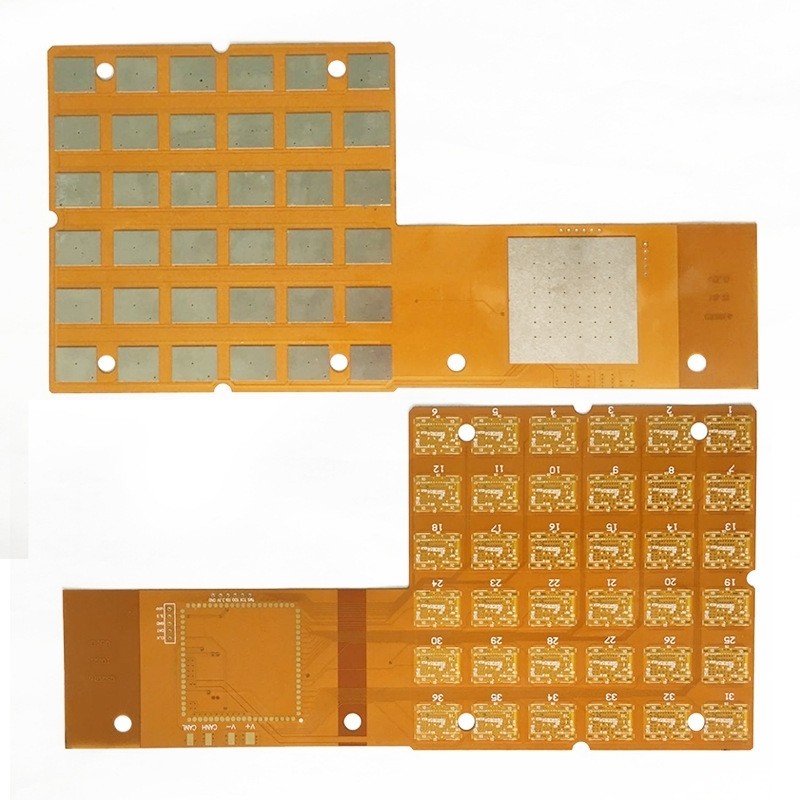

CCD Semi-auto thick film circuit screen printing machine is suitable for thick film circuit.

Detailed

Introduction

Specifications

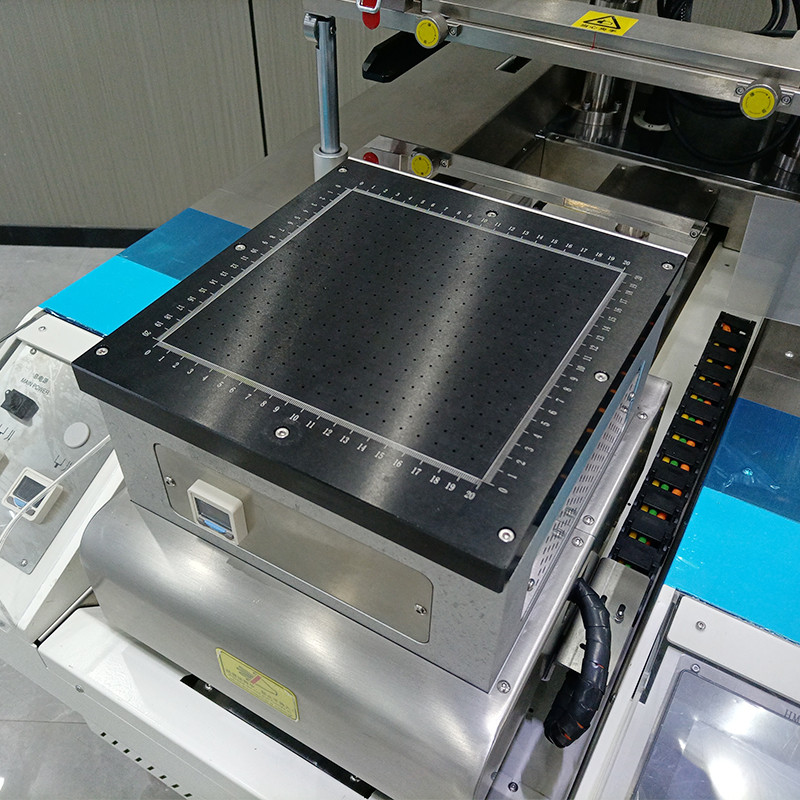

Vacuum bed: 230*230 mm

Max screen printing size: O.D 320*320mm

Substrate height:5 mm

Printing accuracy: 0.02 mm

Printing thickness deviation: 0.002mm

Printing capacity: 800pcs/hour

Air source: 0.4~0.6Mpa

Voltage: AC220V/50/60Hz

Power supply: 1kW

Weight: 370kg

Dimension: 123*740*134cm

Features

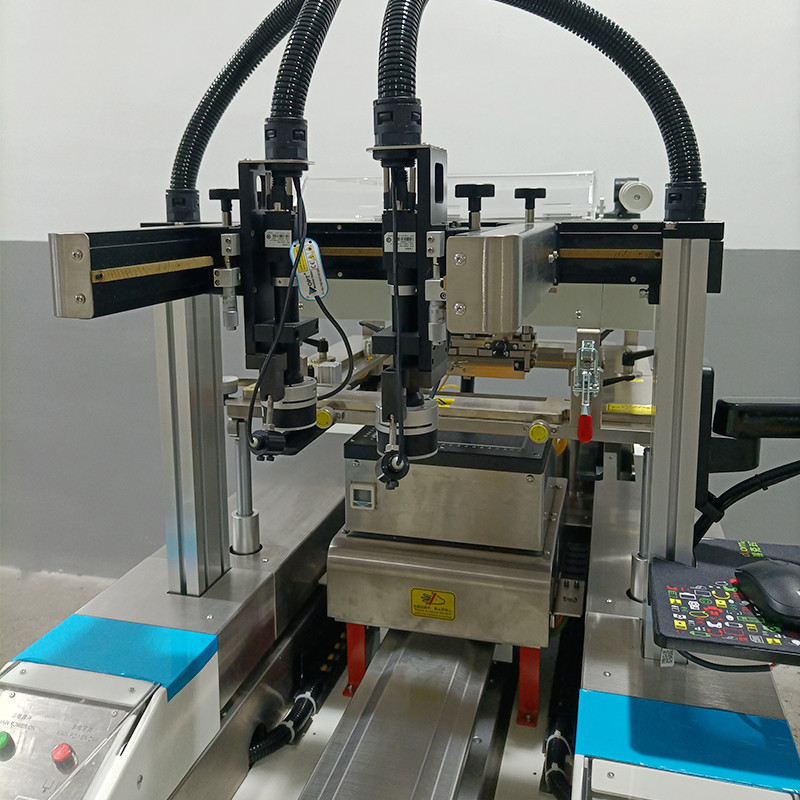

1. Squeegee carriage on Hard Chrome Plated solid steel shaft with linear bearing motion.

2. Adjustable screen frame holder

3. Variable printing stroke length

4. Single/Double stroke selection

5. Parallel screen frame movement(Convenient for spot UV varnish and low viscosity inks to avoid ink spillage all over the screen)

6. Peel off mechanism (To achieve fine reproduction of halftone dots and avoid smudging, bleeding and smearing)

7.Adjustable squeegee angle from 0 to 30º

8.Aluminium extruded squeegee holder & coater for even pressure

9.Bed movement for registration x, y, & Rotary ±10 mm

10.Emergency Rod / Stop for safety of operator

11.Castor wheels for easy mobility

12.Printing operation by foot switch or automatic cycle, with dwell timer 0-10 sec.

Detailed Images

Application

Why Choose TAOXING

Industrial Precision Screen Printing Equipment Manufacturing - TAOXING

TAOXING Specialty Screen Printing Machine is a leading manufacturer and supplier of specialty screen printing machines in China, with more than 10,000 devices installed and running in dozens of industries.

We have developed a number of patents and proprietary products, and continue to provide cost-effective and simple solutions for automating the flat and cylindrical screen printing production process in a variety of applications, including glass, electronics, bottles, ceramics, automobiles, printed advertising, etc.

TAOXING has been providing customers with professional screen printing machinery and its related equipment. With advanced technology and 20 years of experience, TAOXING ensures that every customer's needs are met.

Maintenance and Care Precautions

In order to ensure the stability and long-term performance of the equipment, regular maintenance is recommended, including cleaning the CCD camera, adjusting and replacing printing parts, checking and calibrating the registration system, etc.

Download document

FAQ

-How does a CCD visual system work?

Our CCD visual system uses advanced image processing technology to capture marks or specific patterns on printed materials through a camera, and then accurately locates each printed color layer to achieve high-precision registration.

- Why choose a CCD registered screen printer?

A CCD registered screen printer can significantly improve printing accuracy and production efficiency, especially in printing projects that require complex multi-color alignment. It can not only reduce scrap rates, but also save production time and labor costs.

What industries is this equipment suitable for?