New CCD Semi-Auto Thick Film Screen Printing Machine TX-3535-CCD for Ceramic Circuit Board

- group name

- Semi-Automatic Flat Screen Printing Machine

- Min Order

- 1 set

- brand name

- TAOXING Screen Printing Machines Manufacturer

- model

- TX-3535-CCD

- Nearest port for product export

- Shanghai, Ningbo, Shenzhen, Yiwu

- Delivery clauses under the trade mode

- FOB, CFR, EXW

- Acceptable payment methods

- T/T, D/P D/A, Credit Card, PayPal, Westem Union

- update time

- Mon, 02 Mar 2026 07:42:31 GMT

Paramtents

Printing size 350mm*350mm

Packging & Delivery

-

Min Order1 set

Briefing

CCD semi-automatic thick film printer uses high-precision CCD positioning system to ensure accurate pattern printing, suitable for thick film production of electronic components. It has the characteristics of automatic alignment, high efficiency, high repeatability, and easy operation.

Detailed

Application Fields:

Widely used in touch screen circuits and BM printing, ceramic capacitors, resistors, thick film circuits, ceramic circuits, filters, glass glaze potentiometers, dielectric antennas, ceramic metallization, RFID, sensors (piezoresistive, capacitive) integrated LED lamp holders, piezoelectric ceramic components, LED ceramic substrates, LTCC, MLCC, filters, ceramic thick film circuits, solar silicon wafers, chip components and electronic component printing process manufacturing. (It can realize buried hole printing and through-hole printing) .

Parameters and Specifications:

Specifications

Platform size: 450*600 mm

Maximum screen size:600*950mm

Height from platform to ground:900mm

Scraper stroke: MAX 350mm

Scraper speed: 5~ 350mm /sec

Air source: 0.6-0.8 MPa 50L / min

Voltage: AC220V 3.5KW

Weight: 400kg

Dimension: 1100*850*1700mm

Performance Characteristics:

1. The printing platform X, Y, θ automatically aligns the “+”, “o” and “outline” marks for printing through CCD;

2. This machine is a standard thick film circuit printer, the main features of which are ease of use, high efficiency and high precision;

3. The whole extrusion casting of the machine head adopts full motor design, and the running table, scraper, printing and vacuum are all driven by motors;

Machine Images:

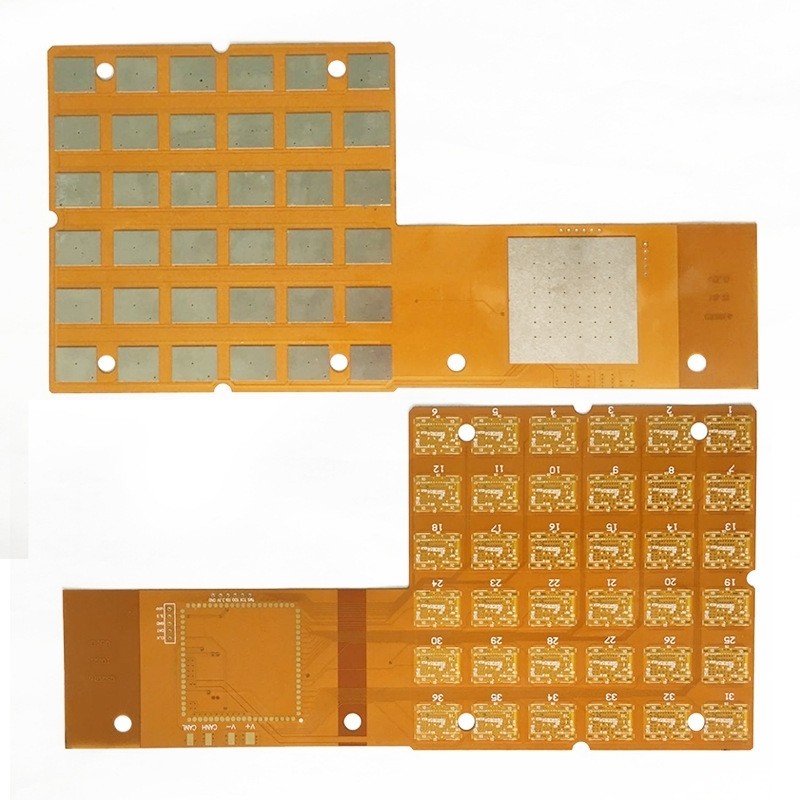

Printing Samples:

Maintenance and Care Precautions:

In order to ensure the stability and long-term performance of the equipment, regular maintenance is recommended, including cleaning the CCD camera, adjusting and replacing printing parts, checking and calibrating the registration system, etc.

FAQ:

-

How does a CCD visual system work?

Our CCD visual system uses advanced image processing technology to capture marks or specific patterns on printed materials through a camera, and then accurately locates each printed color layer to achieve high-precision registration.

-

Why choose a CCD registered screen printer?

A CCD registered screen printer can significantly improve printing accuracy and production efficiency, especially in printing projects that require complex multi-color alignment. It can not only reduce scrap rates, but also save production time and labor costs.

What industries is this equipment suitable for?